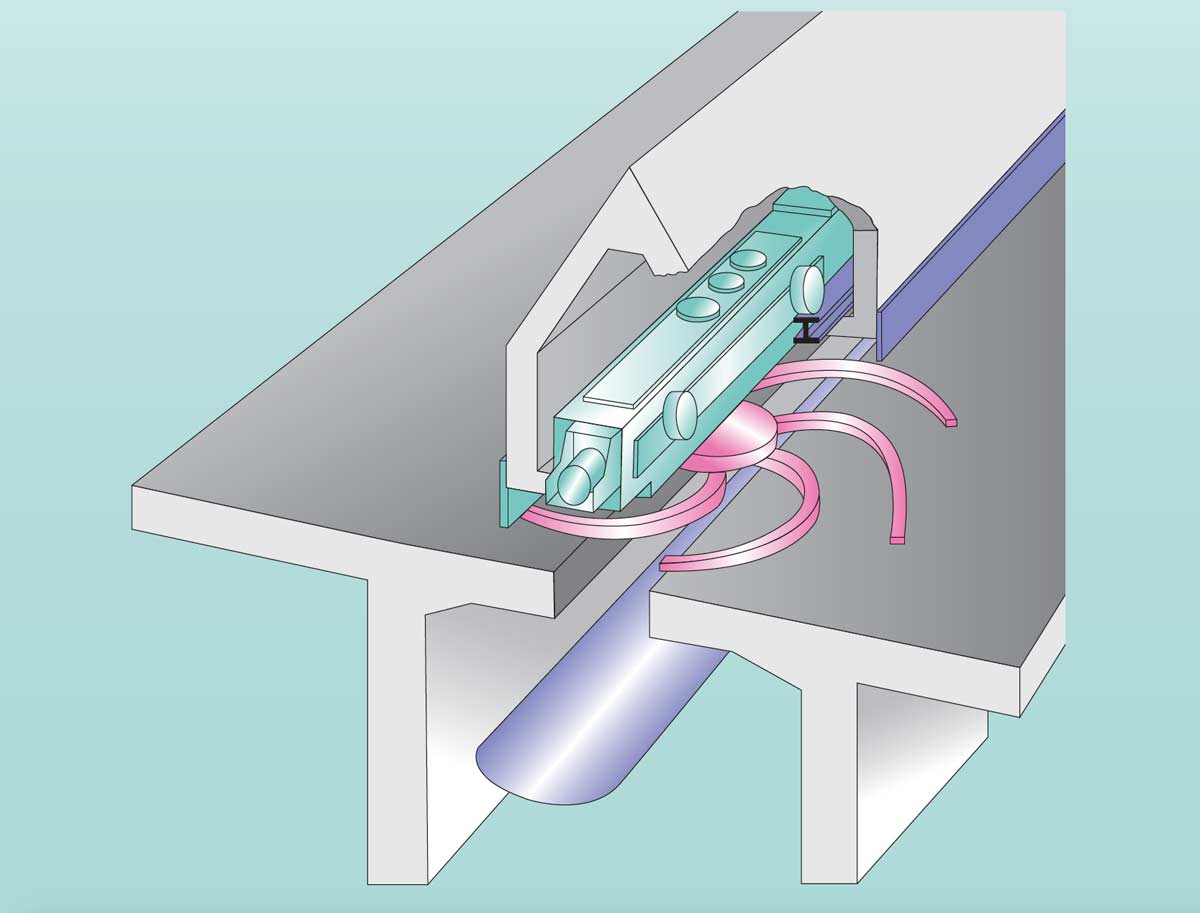

Bunker Discharge Machine (BDM)

Functional Description

The task of the BDM is to extract wet, cohesive, coarse or abrasive non free flowing bulk materials from bunkers, hoppers, bins, silos, stockpiles and dome type storages. The arms of the BDM rotate and reclaim bulk material from the bunker shelf onto a conveying system. The BDM can travel automatically and self-propel itself through a tunnel located under the stored bulk material. The rotating discharge arms convey the bulk material toward the opening in the center of the floor. BDM’s are available in a variety of designs and configurations to meet many applications. The BDM’s discharge wheel has six logarithmic shaped discharge arms which guarantee consistent feeding of any bulk material. The arms are bolted to a hub which is connected by a shrink disk to the output shaft of the reducer. Discharge arms are lined with wear resistant liner plates designed to increase the life of the discharge arms. WTW’s BDM is the industry standard for reliability in continuous operation.

Technical Data

Available in sizes from 2 to 5 meters in diameter, with flow rates of 10 to 4,000 t/h.