Alternative Fuels & Biomass Handling

Bulk Materials Handled

Refuse Derived Fuels (RDF), Tire Derived Fuels (TDF) and Municipal Solid Wastes (MSW)

WTW Americas is an industry leader in handling alternative fuels and offers equipment compliant with any ATEX design or explosion protection.

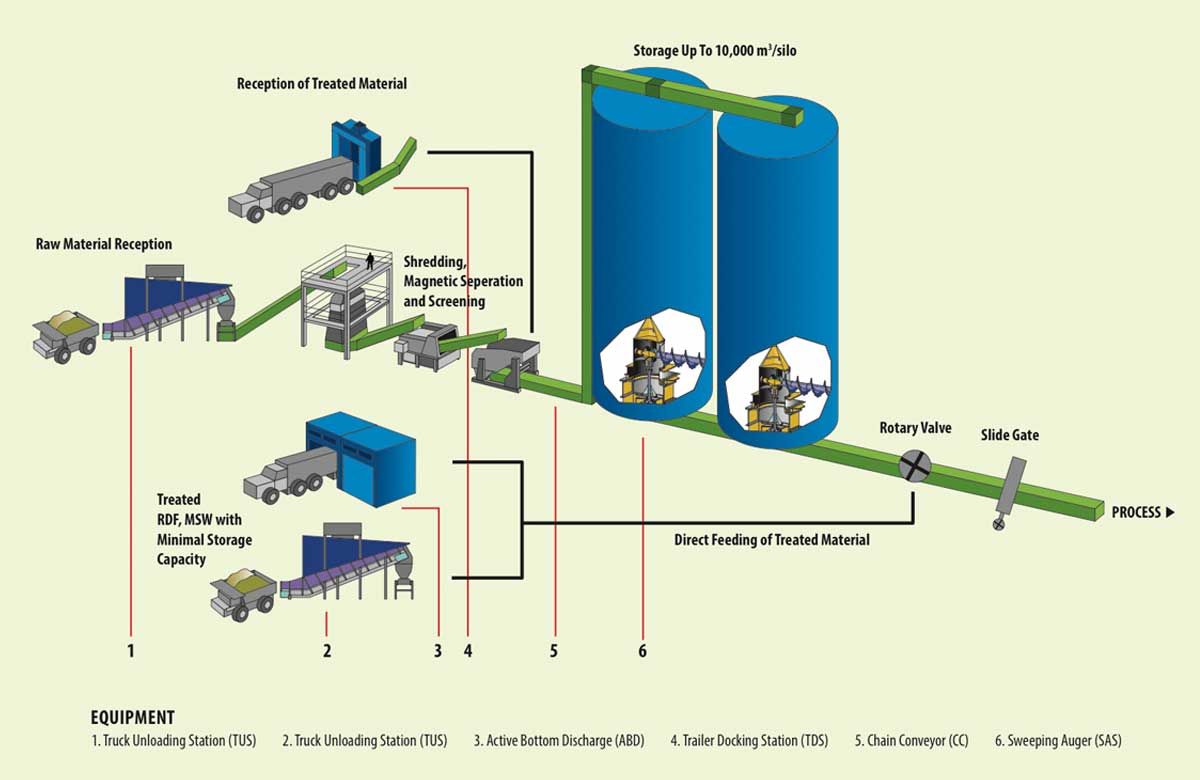

We can provide the following:

- Dust tight material reception by truck, train or barge

- Screening, magnetic separation, and shredding

- Transporting, weighing, storing and dosing

We can provide complete turn-key systems, or individual components for your process and handling needs.

Recommended Equipment

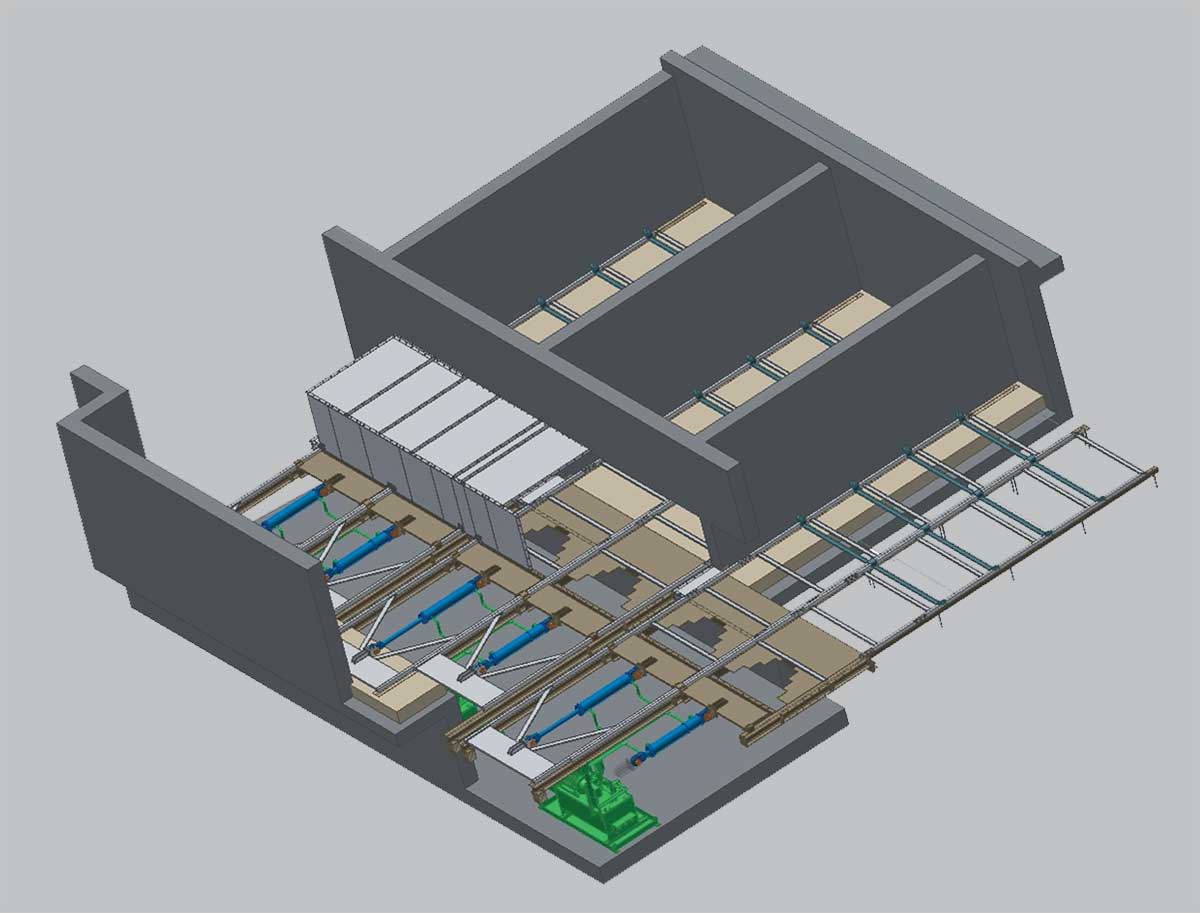

Active Bottom Discharger (ABD)

The Active Bottom Discharger is a very simple, low maintenance answer to receiving raw material from trucks, trailers, or front end loaders and leading it into a process. The ABD is installed in a pit allowing the various vehicles to unload directly into it. Once the material is transferred into the ABD moving rakes push the material toward the aft wall against the stationary ladders.

The ABD is capable of receiving materials such as biomass, industrial or municipal wastes, woodchips and bark, and complete or shredded tires.

Truck Unloading Station (TUS)

The WTW Americas Truck Unloading Station is one of our most popular, and requested pieces of equipment. This custom designed machine allows clients to receive bulk materials that can be led directly into their process, with no need for expensive civil work, continuous manpower, underground pits, or other conveying systems. Trucks, or front end loaders can simply tip their load into the reception area and pull away. The material is then fed, at a controlled pace, into the process. The TUS can easily be relocated or made fully mobile using tires.

The TUS is capable of receiving all materials and alternative fuels such as dry or dusty powders, municipal and industrial solid waste, biomass, and other treated or untreated materials.

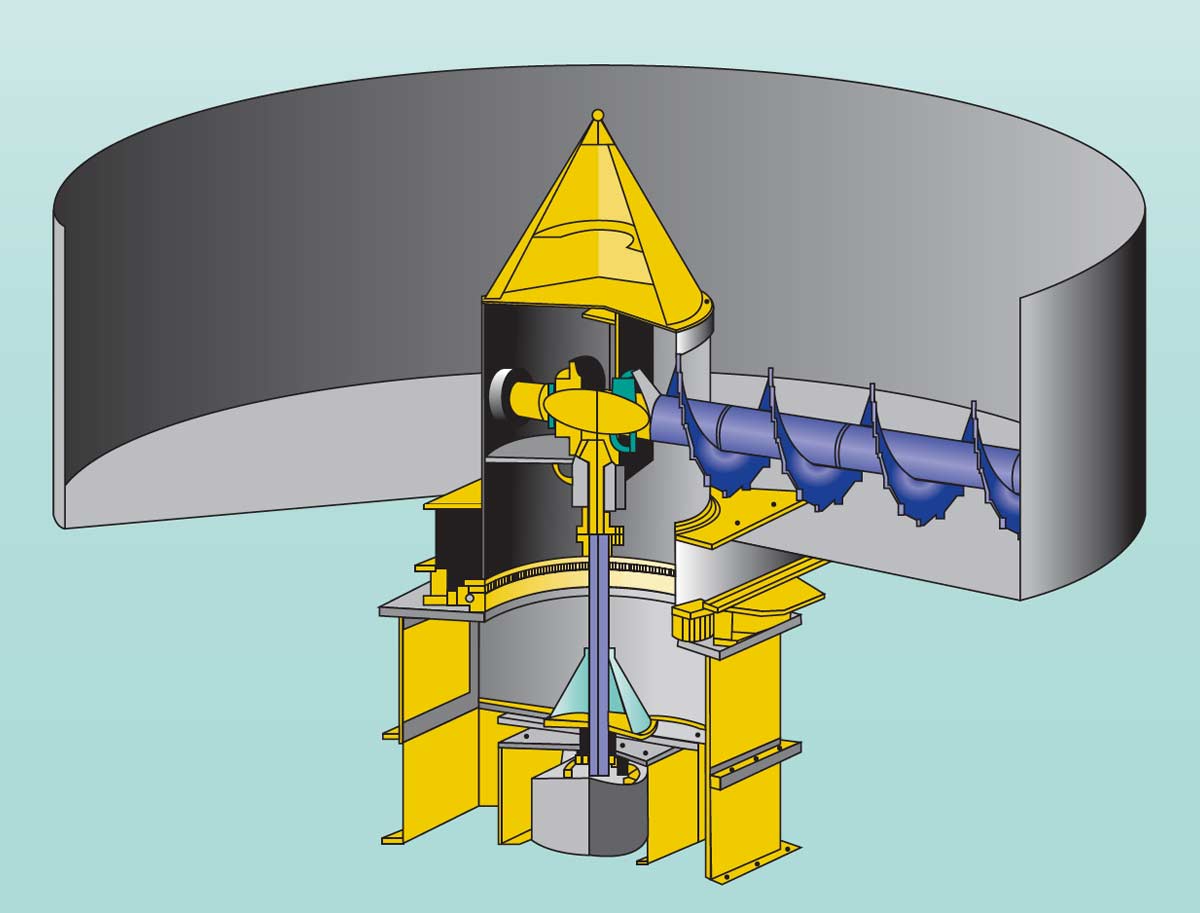

Sweeping Auger (SAS)

The Sweeping Auger is designed to be mounted at the bottom of silos or bunkers with diameters up to 25m.

It is used to discharge lighter density materials. Operating in a circular motion, the large screw, which also circulates, draws a uniform disk of material towards the central discharge. The SAS can be retrofitted into existing installations saving customers money on building new storage facilities.

The SAS is capable of receiving, and discharging, materials such as bypass dust, wood chips, plastic and plastic pellets, or most other lighter density product after it has been pre-treated.

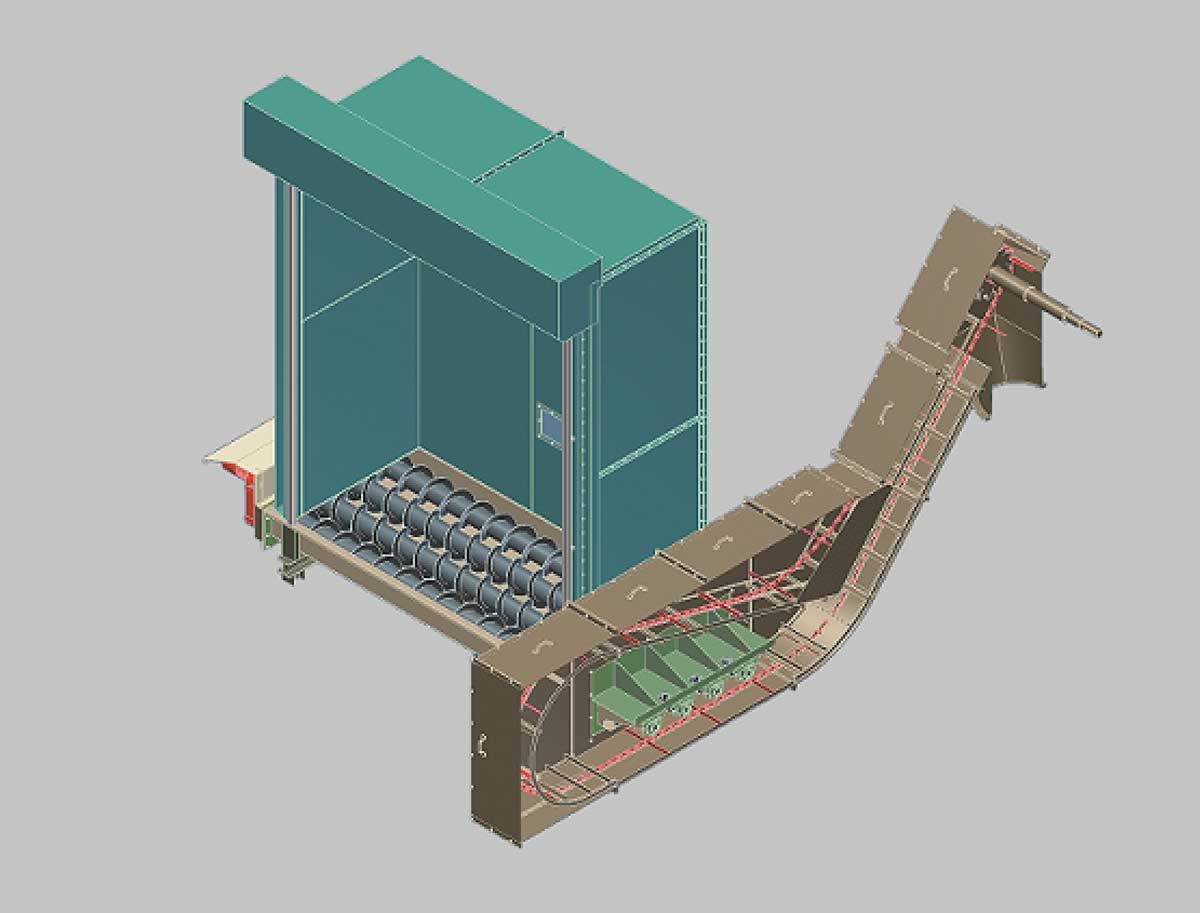

Trailer Docking Station (TDS)

The WTW Americas Trailer Docking Station is the industrial answer to receiving treated materials from walking floor trucks. Optional hydraulic systems allow a trailer to be left connected to the TDS while the truck pulls away, thereby making the walking floor trailer an automatic material buffer or storage device. As material is slowly emptied from the trailer into the reception area, an active bottom feeder conveys the material into a chain conveyor, and then into the intended process. A double docking station would maximize productivity by allowing continuous feed of material. The TDS requires no civil engineering and no pit, making it a very easy and economical solution for receiving material from a trailer.

The TDS is capable of receiving most treated materials used in burning alternative fuels.

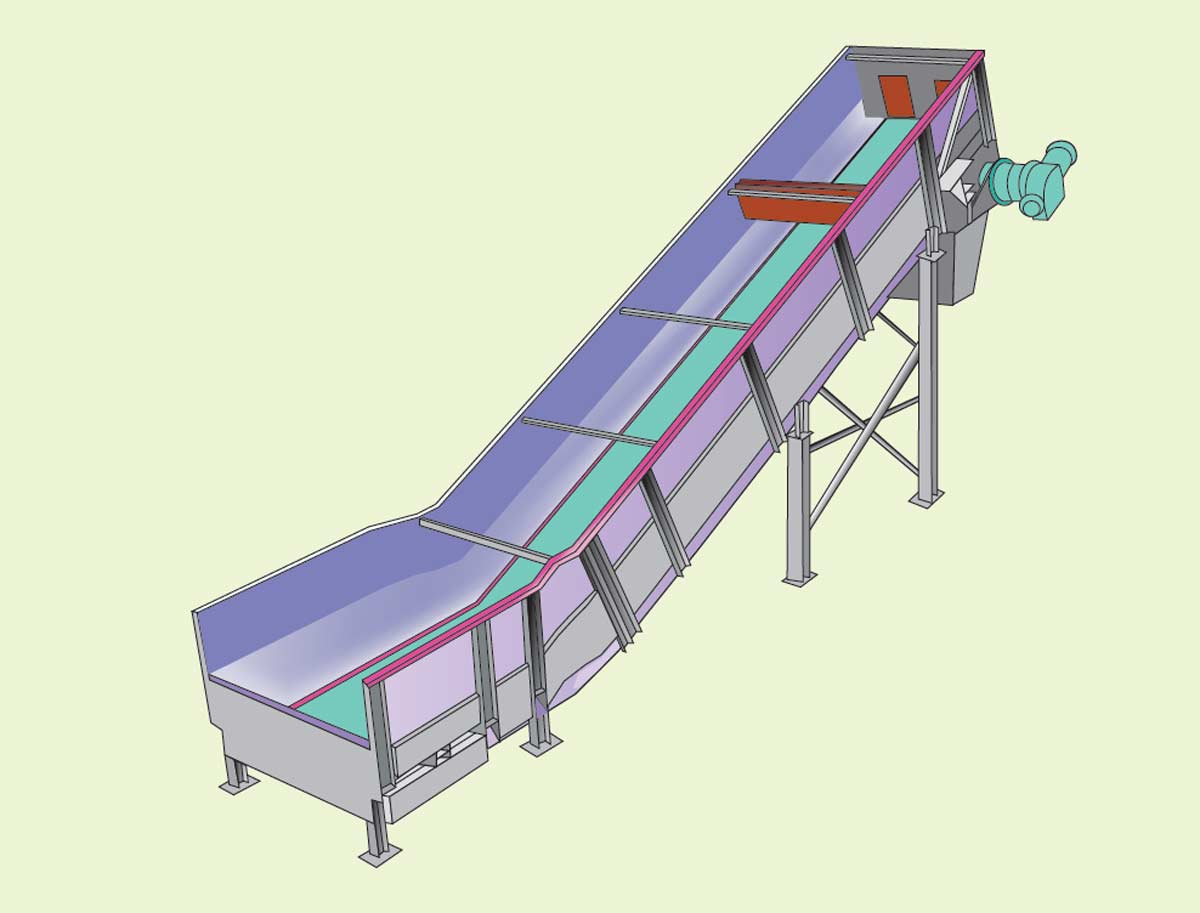

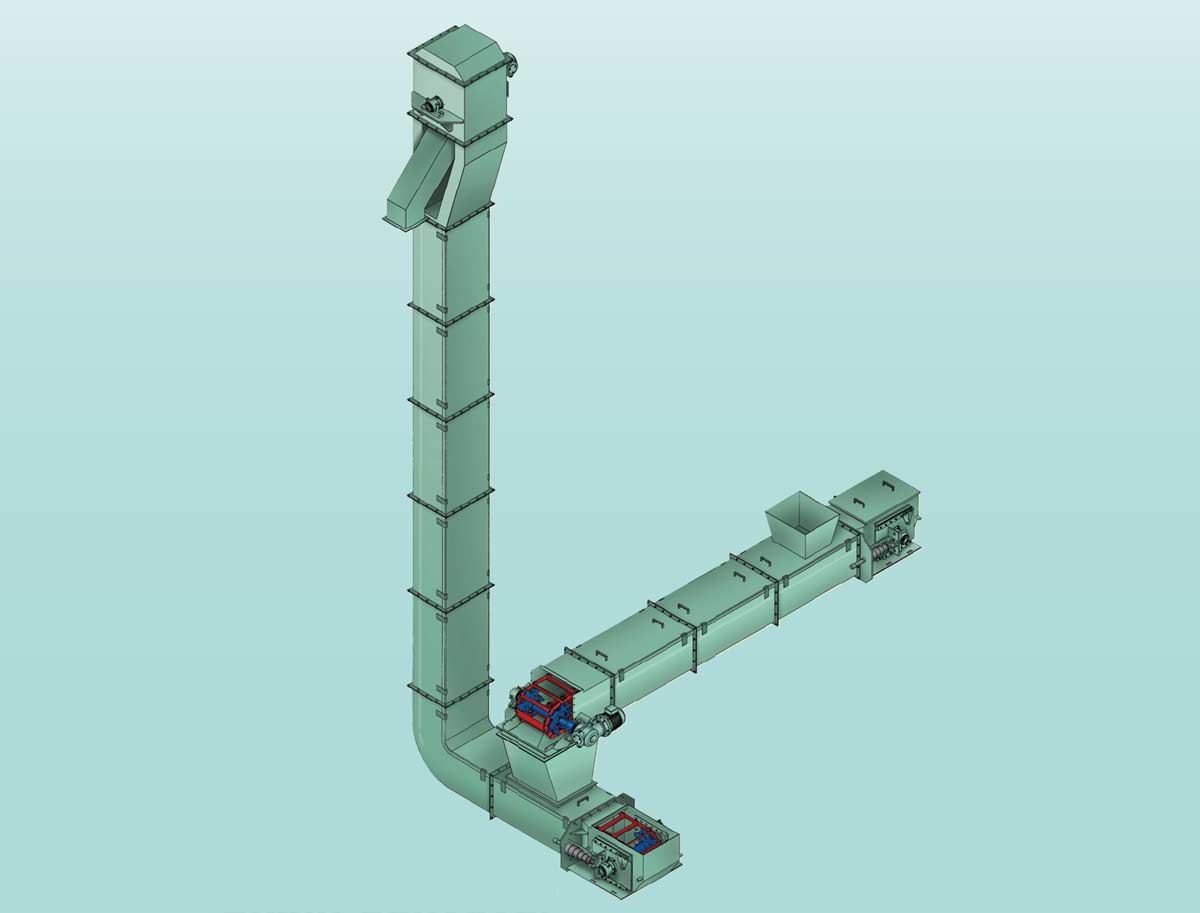

Chain Conveyor (CC)

The WTW Americas Chain Conveyor is a heavy duty and reliable means of transporting material from one or more stages of a process to the next. With its dust and gas tight construction, as well as its explosion proof design, the CC is the most reliable means of conveying in any industry. It can successfully handle sticky or hot materials up to 750°C. The CC is capable of conveying most materials such as wood chips, sawdust, plastic, biomass, and municipal solids waste.

Operational Turn-Key Alternative Fuels Handling Installations

Bialystok Power Plant, Poland

Commissioned and operational in the autumn of 2008 by WTW, this complete turn-key alternative fuels handling system receives untreated material. Wood waste and wood chips are received by using Active Bottom Dischargers at a capacity of 100 t/h (315 m3/h). The material is conveyed through a magnetic separation and screening process at a rate of 30 t/h (90 m3/h) by Chain Conveyors which transport the material into 2 silos capable of storing 158 ton (5000 m3) each. At the base of each of these silos are Sweeping Augers which discharge the stored material at 30 t/h (90 m3/h) onto conveyors that transport it into the boiler.

Kinegad Cement Plant, Ireland

Commissioned and operational in the spring of 2008 by WTW, this complete turn-key alternative fuels handling system receives pre-treated material. Wood chips, sawdust, plastic and paper fluff are received using 2 Active Bottom Dischargers (ABD) at a capacity of 4 t/h. The ABD's also act as hoppers capable of storing 200 m3. The material is then conveyed by a weigh belt system to a double sandwich conveyor belt which transports it to the calciner tower.

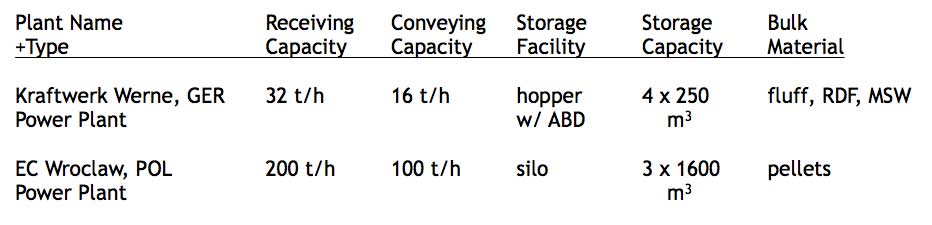

Here are a few more examples of completed turn-key alternative fuels handling systems: